Honing is the finishing

of internal dimensions of automobile cylinder heads

and other components when an excellent and accurate

finish is required.

Super finishing is the

production of very high finishes, as high as 0.02 um,

on the outside diameters of components and inside diameters

of bearing rings, bearing races and all other components

where friction is to be reduced to the barest minimum.

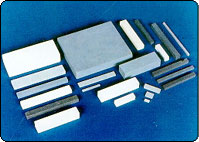

Honing and Super finishing

are generally performed with squire, rectangular or

specially shaped sticks or blocks. Honing stones can

be used for all forms of honing, vertical, horizantal

and flexible or oscillating.

Honing can vary from

bore diameters of approximately 25mm to 900mm, on components

of up to 9 meters in length. Stock removals can be as

high as 21.3 cu.cm. of metal removal per minute while

finishes up to 0.05 um are possible with better control.

Ion honing, the abrasive

stones are held in the Honing head in sets of 4, 6 or

8 pieces. The Honing Process comprises longitudinal

and rotary motions of the honing head to generate a

cross hatch pattern.

This pattern is necessary

to provide lubrication by retention of cutting fluid.

The cutting fluids normally used are straight cutting

off, kerosene and mineral seal oil.

Super finishing is generally

done in stages of 2, 3 or 4. Roughing is done with White

Aluminium Oxide stones of grit sizes 400, 600 and 800.

The finishing is done with Silicon Carbide stones of

grit sizes 800, 1000 and 1200.

Factors that affect

Honing and Super finishing are

Certain Honing &

Super finishing stones, particularly when used for steel,

are treated with sulphur to increase stone life and

prevent loading.

Some Useful hints:

-

To avoid glazing,

reduce spindle rpm, increase reciprocating speed

or use softer grade of stone.

-

To avoid tapered

or out-of-form work due to excessive wear on stone,

increase spindle rpm, reduce reciprocating speed,

reduce pressure or use harder grade stone.

-

For components having

a thin wall section and / or comparatively soft

stone.

-

To avoid excessive

heat generation, use copious flow or coolant, softer

grade stone and lower grinding pressures.

-

Hardness of the

stone should be decreased as areas of stone in contact

with work increases and vice versa.

|